Technical Articles

NANBEI Is Professional On Providing One-step Solution Of Laboratory Instruments And Equipment

Glass reactors are essential equipment in chemical, pharmaceutical, and food processing industries.

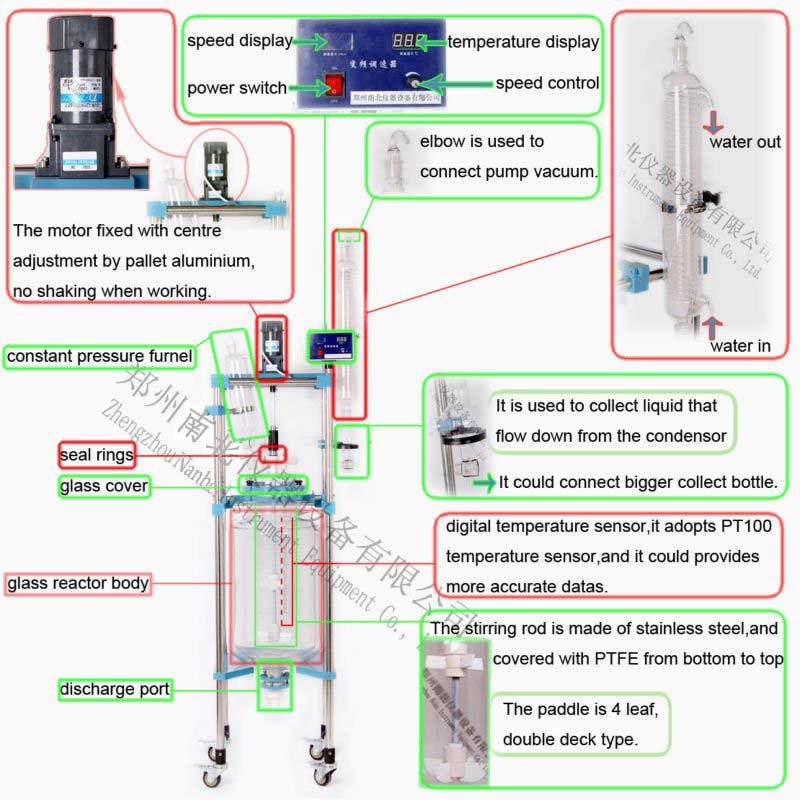

Among various types, the **double-layer jacketed glass reactor** stands out for its unique combination of safety, efficiency, and versatility.

Below we explore its 6 operational advantages:

1. **Precise Temperature Control**

The circulating fluid in the jacket enables **±0.5°C temperature accuracy**, critical for sensitive reactions like polymerization or crystallization. [Learn more about reactor temperature systems→]

2. **Superior Chemical Resistance**

Constructed with **high borosilicate glass** (3.3 expansion coefficient), it withstands acids, alkalis, and organic solvents at temperatures up to 300°C.

3. **Real-Time Reaction Monitoring**

Full visibility allows observation of phase changes, precipitation, or color shifts – vital for **process optimization** and safety control.

4. **User-Friendly Operation**

Integrated with **digital control systems** for stirring speed, temperature, and vacuum/pressure. Reduces human error by 40% (ISO 9001 certified).

5. **Enhanced Safety Protocols**

Features include:

- PTFE sealings with leak detection

- Automatic pressure relief valves

- Explosion-proof motor options

6. **Low-Maintenance Design**

Smooth glass surfaces prevent residue buildup. Modular components enable quick seal replacement (<15 minutes).

Widely used in:

- Pharmaceutical synthesis (API development)

- Nanomaterial production

- Essential oil extraction

- Petrochemical pilot testing

> **Pro Tip:** Perform monthly seal integrity checks and calibrate temperature sensors quarterly.

> *Need help selecting a reactor? [Contact our lab equipment specialists] for a free consultation.*